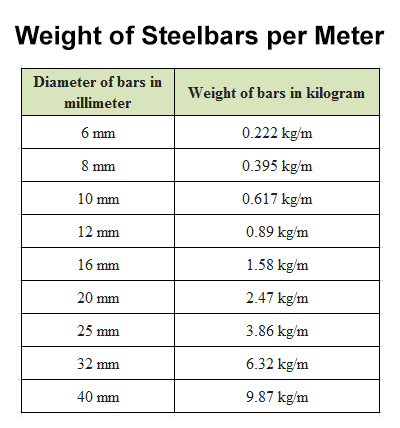

The weight of a Reinforced steel Rod can be calculated with the use of the system:

Weight

= π×Diameter2`×Length×Density/4

Where:

π is a mathematical regular about identical to a few.14159.

Diameter

Diameter is the diameter of the metallic rod.

Length

Length is the length of the metallic rod.

Density

Density is the density of metal, which is normally around 7.Eighty-five grams according to cubic centimeters.

Let’s destroy the method:

Calculate the location of the pass segment of the rod:

π×Diameter`2 /4

Multiply the move-sectional area by using the length of the rod:

π×Diameter `2 ×Length /4

Multiply the result by way of the density of the metal to get the weight.

For example, shall we embrace you’ve got a bolstered steel rod with a diameter of 10 millimeters and a duration of 1 meter:

Weight=

3.14159×(10mm) 2 ×(1m)×7.85g/cm 3 /4

You can convert the units as needed to match your alternatives (e.g., meters to centimeters, grams to kilograms) for the final weight calculation.

Keep in mind that this component provides an approximation, because the actual weight may also vary based totally on elements, including the unique alloy of steel used and ability variations in density. Additionally, the density value used here is a commonplace approximation; you may need to use a greater unique fee when you have unique data approximately the metallic alloy.

Certainly! If you need extra particular facts on calculating the burden of bolstered steel rods, you may also not forget the subsequent:

Density of Steel:

The density of steel can vary based totally on the alloy. The generally used value of 7.Eighty-five grams consistent with cubic centimeters is a standard average. For greater unique calculations, you may use the unique density of the metal alloy you’re running with.

Unit Conversion:

Ensure that every one of the measurements are in the identical gadgets. For example, if the diameter is given in millimeters, you may want to convert it to meters for consistency.

Weight in Different Units:

After calculating the load in grams, you would possibly need to convert it to other devices which include kilograms (divide by using 1000) or metric tons (divide by means of one million) for realistic functions.

Use of Reinforcing Material:

If the metal rod is part of a strengthened concrete shape, you might also need to take into account the burden of the concrete itself and another reinforcing substance.

Safety Factors:

In engineering and production, protection factors are frequently applied to calculations to account for uncertainties and unexpected hundreds. The calculated weight may be expanded through a protection thing to make sure that the structure can deal with potential variations and masses.

Tensile Strength:

If you are interested about the energy of the metallic, you can need to not forget factors together with the tensile energy of the fabric, in particular if the rod is a part of a structural factor subjected to sizable loads.

Always consult applicable engineering requirements, codes, or recommendations to your particular utility, as structural layout involves extra considerations beyond easy weight calculations. If you’re operating on a construction task, it is beneficial to have a qualified structural engineer to ensure the protection and integrity of the shape.

Certainly! Here are some extra issues associated with bolstered metallic rods:

Corrosion:

Corrosion can affect the load and power of metallic over time. In corrosive environments, the weight reduction because of corrosion needs to be taken into account. This may additionally contain extra shielding measures or periodic inspections to assess the situation of the steel. How to Calculate Cement, Sand, Aggregate ratio of a Concrete

Bar Markings:

Reinforced steel rods often come with markings that provide records approximately their specs, which include the grade of metallic, manufacturer, and manufacturing info. Understanding these markings is crucial for correct calculations.

Cutting and Bending Losses:

When the usage of steel rods are in construction, there may be losses related to slicing and bending the rods to healthy unique shapes and sizes. These losses have to be considered inside the usual cloth estimation.

Material Waste:

Construction tasks often generate cloth waste. When estimating the amount of metallic required, it is commonplace to encompass an aspect for cloth waste to account for inefficiencies in slicing, managing, and installation.

Load Distribution:

In structural engineering, it is important to take into account how masses are distributed within a structure. The weight of the steel itself is part of the burden, and engineers need to make certain that the shape can aid no longer only the lifeless load (everlasting loads just like the weight of the structure) but also stay loads (variable loads like humans, fixtures, or gadget).

Dynamic Loads:

If the structure is subjected to dynamic loads, such as those from transferring motors or machinery, the layout has to account for the additional stresses and forces that those dynamic hundreds impose on the shape.

Fire Resistance:

Steel loses its electricity below excessive temperatures. If the structure is expected to be uncovered to the hearth, engineers need to not forget the hearth resistance of the substances and may encompass fireproofing measures.

Environmental Conditions:

The environment wherein the shape is positioned can also impact the overall performance of the metal. Extreme temperatures, publicity to chemical compounds, and other environmental elements ought to be taken into consideration within the design and material selection.

Always adhere to relevant building codes, standards, and policies precise to your region and assignment requirements. Consulting with a structural engineer or qualified experts is essential for accurate and safe layout and creation.