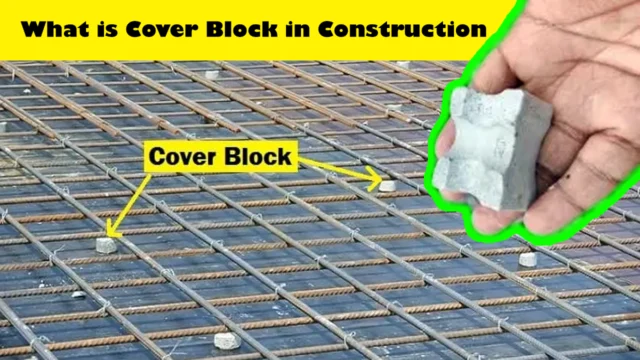

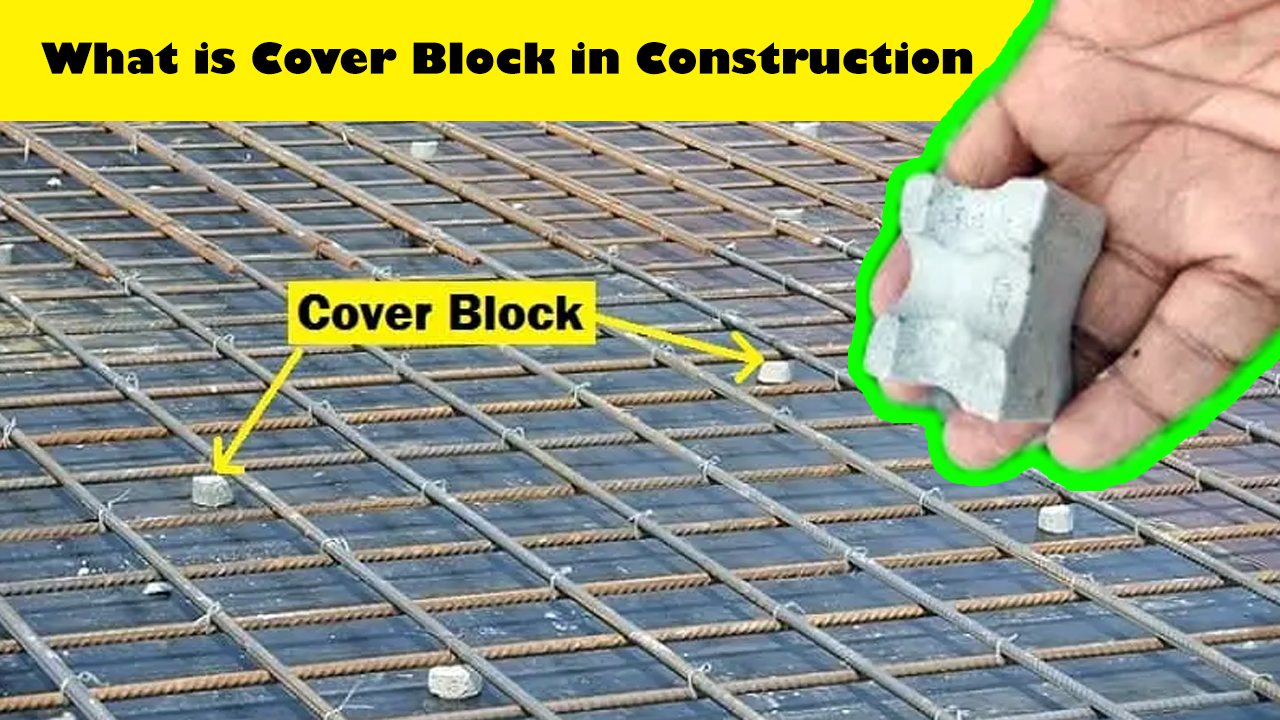

What is Cover Block in Construction

In construction, a “cover block” generally refers to a small piece or block manufactured from concrete or different materials that is used to preserve a designated distance between reinforcing bars (rebar) and the outer floor of a concrete structure. The primary reason of cover blocks is to make sure that the reinforcing steel is located at the proper intensity in the concrete, imparting good enough safety in opposition to corrosion and making sure the structural integrity of the finished element.

Reinforcing bars are generally used in concrete construction to decorate its tensile electricity and typical sturdiness. However, to maximize their effectiveness, it is crucial to put the rebar on the proper intensity inside the concrete. This depth is frequently specified in creation drawings or structural engineering plans.

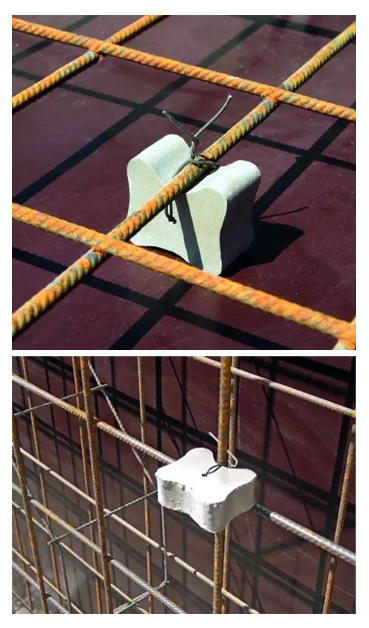

Cover blocks are placed around the rebar before the concrete is poured to help obtain the preferred spacing and make sure that the rebar is sufficiently blanketed with the aid of the concrete. The cover blocks are available numerous shapes and sizes, and their selection relies upon on the specific necessities of the development mission.

It’s essential to follow construction codes and specs to determine the precise dimensions and location of cover blocks, as they play a vital function in the long-time period durability and overall performance of the concrete shape. Incorrect placement or inadequate cowl can result in problems inclusive of corrosion of the reinforcing metallic, compromising the structural integrity of the development.

Materials: Cover blocks are normally manufactured from materials which can be well suited with concrete, consisting of concrete itself, plastic, or other non-corrosive substances. The desire of fabric relies upon on elements including the required energy, sturdiness, and resistance to environmental conditions.

Shapes and Sizes: Cover blocks are available in numerous sizes and styles, consisting of cylindrical, square, or circular shapes. The dimensions of the quilt blocks are certain primarily based on the thickness of the concrete cowl required for the reinforcing bars. Different shapes and sizes are used based totally on the precise structural requirements of the development challenge.

Placement: Cover blocks are strategically located alongside the length of the reinforcing bars to preserve a constant and special distance between the surface of the concrete and the outermost layer of rebar. The proper placement of cover blocks allows in attaining uniform concrete cover, that’s essential for shielding the reinforcing steel from environmental elements.

Concrete Cover: The concrete cover refers to the space among the outer floor of the concrete and the surface of the reinforcing bars. This distance is laid out in design and production files to fulfill structural and sturdiness necessities. Adequate concrete cowl is vital for stopping corrosion of the reinforcing metallic and making sure the overall power of the shape.

Use in Different Structures: Cover blocks are used in various forms of concrete structures, including buildings, bridges, dams, and other infrastructure initiatives. The precise necessities for cover blocks may also vary relying on elements which includes the sort of structure, environmental situations, and layout specs.

Quality Control: During production, it is crucial to make sure that cover blocks are placed as it should be and securely. Quality manipulate measures, along with inspections and adherence to creation standards, are important to assure the right placement and effectiveness of cowl blocks in maintaining the specified concrete cover.

In precis, cowl blocks play a vital function in reinforcing concrete systems with the aid of preserving the suitable spacing among reinforcing bars and the surface of the concrete. Proper installation of cowl blocks is a key thing of ensuring the toughness and structural integrity of a production undertaking.

Concrete Cover Requirements: The required concrete cowl for boosting bars can range based on factors such as the sort of shape, environmental conditions, and the kind of exposure to which the structure will be subjected. Design codes and engineering standards provide pointers for determining the right concrete cover for unique situations.

Corrosion Protection: One of the primary functions of cover blocks is to guard the reinforcing steel from corrosion. Corrosion can occur whilst moisture and environmental factors attain the metallic, and good enough concrete cover furnished by cover blocks enables guard the metal from these destructive results.

Spacer Blocks: In addition to cover blocks, spacer blocks also are utilized in construction. Spacer blocks are just like cover blocks but are generally smaller in length. They are hired to maintain a selected spacing among two layers of reinforcing bars or among a bar and the formwork.

Preventive Measures: Proper installation of cover blocks is a preventive measure in opposition to problems consisting of rusting and deterioration of the reinforcing steel. Corrosion of metallic can compromise the structural integrity of a concrete detail, and cover blocks contribute to the general durability of the shape.

Construction Joints: Cover blocks are frequently used within the place of construction joints where new concrete is poured towards existing concrete. Ensuring the best placement of cowl blocks in such areas is crucial to retaining uniform concrete cowl and stopping capacity weaknesses inside the shape. Also read: What is MLC pipe? advantages of MLC pipes

Fire Resistance: Adequate concrete cover provided via cover blocks additionally contributes to the fire resistance of reinforced concrete structures. The cover enables guard the reinforcing steel from the high temperatures skilled during a hearth, preserving the structural stability of the building.

Load Distribution: In addition to corrosion protection, cover blocks contribute to the distribution of hundreds inside the concrete shape. Proper spacing and placement assist ensure that the reinforcing bars correctly distribute the masses they undergo, enhancing the overall load-bearing capability of the structure.

Specialized Applications: In a few cases, specialized cowl blocks can be used, such as the ones designed for precise kinds of creation elements or to cope with specific assignment requirements. These ought to encompass cover blocks with functions like grooves or clips to facilitate set up.

Understanding the function and significance of cover blocks in creation is essential for builders, contractors, and structural engineers to make certain the safety, durability, and performance of bolstered concrete systems.